“Tensile testing is a common material testing method to apply tension, load and force onto a sample until it breaks apart.”

Tensile testing has been used by quality control departments to assure that their parts & components have product integrity and safety.

Various testing methods

Destructive testing is used in order to discover a material’s mechanical and wear & tear characteristic, reaction, limits and capability. Some of the common methods are:

- Tensile Strength – measures the force or strength required to pull a sample apart i.e. until breakage / failure

- Compression – determines the specimen’s behavior and reaction under a compressive load i.e. when it is compressed, squashed, crushed or flattened

- Bending – determines the material’s ductility or resistance to fracture by deforming it into a curve surface or bend until the point of fracture

- Elongation – similar to the tensile except more focused on studying how far the material can stretch before its breaking point

- Crimp Joint Pull-off Force – pull-off test to determine the force needed to remove the wire-type samples from its joint

- Peel – measures the adhesion (stickiness) strength, especially for tape testing.

- Shear – determines strength of an adhesive i.e. glue / tape; that is applied between samples and pulled until the two samples are separated

And many more!

Collects useful data

Data collected from a tensile test, allows manufacturers to:

- Assist with the product development & design process

- Comply with international & industrial standards

- Determine batch quality & consistency

- Reduce rework material costs & minimise wastage

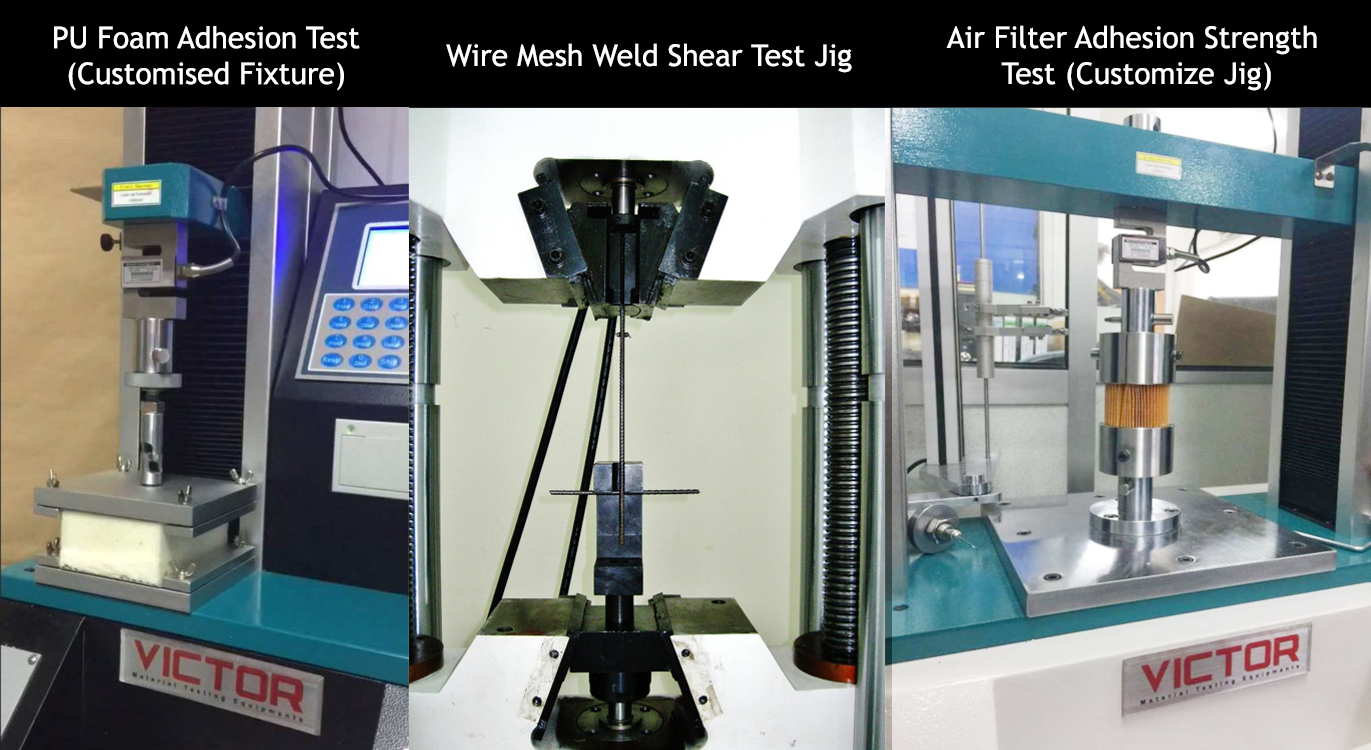

Unique Testing Accessories & Attachments

UTMs can cater to unique testing samples or meet a certain test requirement or methods for industries from metal, plastic, rubber, textile, foam, wood, etc. Thanks to its customisable accessories and grips.

Universal Industrial Application

Tensile testing specialise quality assurance of the components, materials and finished product from various industries from:

- Aerospace & Automotive

- Paper & Cardboard

- Civil Engineering & Construction

- Education & Research

- Electrical & Electronics

- Fabric & Textile

- Food & Beverage

- Packaging

- Furniture & Toys

- Medical items, devices & equipment

- Metal, Steel & Alloy

- Plastic, Rubber & Elastomers

- Production & Manufacturing

- Semiconductors

And many more!

Unsure how to choose the right Universal Testing Machine / material testing method for your application?

Reach out to our expert today for a professional recommendation.

Alvin George, Product Specialist, +6012-2232593, [email protected]

You can browse our list of Material Testing Equipment and Serviceswww.victormaterial.com

Brought to you by, Victor Equipments Resources Sdn Bhd (1021443-H)

.jpg)

Since 2010, VICTOR has companies from:

• Automotive Industries Sdn Bhd (AISB)

• Engtex Ductile Iron Pipe Industry Sdn Bhd

• GHS Food Industries Sdn Bhd

• HELP College University Malaysia

• KYB-UMW Malaysia Sdn. Bhd.

• Shorubber R&D Institute (Malaysia) Sdn Bhd

• TÜV SÜD (Malaysia) Sdn Bhd

• UMW Toyota Motor Sdn. Bhd. and many more!

View original post here |

.jpg)