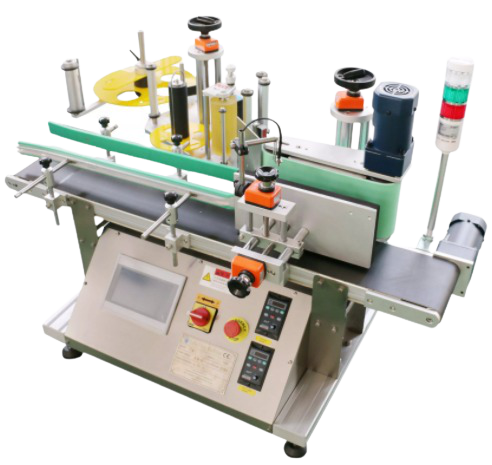

Desktop Labelling Machine

Summary

The NP-AT desktop paste standard sample machine is designed to achieve rational production goals. Labeling is automated operation, simple operation, high efficiency, beautiful and neat. Suitable for round bottle and flat bottle in the pharmaceutical, food, daily chemical industries, etc. and can label wrap-around labels and semi-circle labels. Be optional of automatic bottle feeding turntable, which can be directly connected to filling line, and automatically feed bottles into the labeling machine to improve efficiency. Be optional of ribbon coding and labeling machine, which can print production date and batch number online, reduce bottle packaging procedures and improve production efficiency.