Surface and Coating Quality Testing

What is Surface and Coating Quality Testing?

Surface and coating quality testing encompasses a range of techniques used to evaluate the surface characteristics and coating thickness of materials. These tests ensure that surfaces and coatings meet specific requirements for appearance, functionality, and durability. Common tests include surface roughness measurement, coating thickness testing, adhesion testing, and surface contamination analysis.

Why is this Surface and Coating Quality Testing important?

Surface and coating quality testing is essential for several reasons:

- Ensures Product Quality: Verifies that surfaces and coatings meet required specifications and standards.

- Enhances Performance: Ensures that coatings provide the necessary protection and functionality, such as corrosion resistance or aesthetic appeal.

- Increases Durability: Identifies defects that could lead to premature failure, ensuring long-lasting performance.

- Compliance with Regulations: Helps manufacturers comply with industry standards and governmental regulations.

- Cost Efficiency: Reduces the risk of rework and product recalls by detecting issues early in the production process.

The principle behind surface and coating quality testing involves various techniques to evaluate surface characteristics and coating thickness. Key concepts include:

- Surface Roughness Measurement: Assesses the texture of a surface by measuring the vertical deviations from its ideal form. This is critical for applications where surface smoothness affects performance.

- Coating Thickness Testing: Measures the thickness of a coating applied to a substrate. This ensures that the coating provides adequate protection and meets design specifications.

- Adhesion Testing: Evaluates the bond strength between a coating and its substrate to ensure durability and resistance to peeling or flaking.

- Surface Contamination Analysis: Detects and quantifies contaminants on a surface that could affect coating adhesion or performance.

These standards provide guidelines on test procedures, equipment, and data analysis to ensure reliable and reproducible results in surface testing and coating thickness testing.

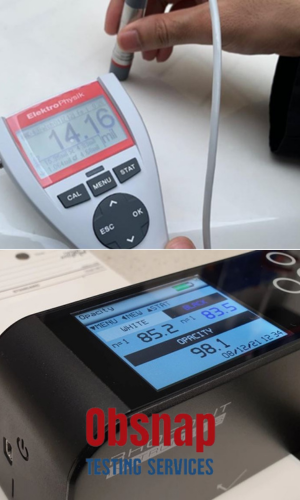

Various tools and instruments are used in surface and coating quality testing, depending on the specific method employed. Key tools include:

- Surface Roughness Testers: Instruments that use stylus profilometry or optical methods to measure surface texture.

- Coating Thickness Gauges: Devices that use magnetic induction, eddy current, or ultrasonic methods to measure coating thickness.

- Adhesion Testers: Tools such as pull-off testers or cross-hatch cutters used to assess coating adhesion.

- Surface Contamination Test Kits: Kits that include swabs, solvents, and analyzers to detect surface contaminants.

Performing surface and coating quality testing involves several steps, which vary depending on the specific method: Surface Roughness Measurement:

- Preparation: Clean the surface to remove any loose particles.

- Measurement: Use a surface roughness tester to scan the surface and record the roughness profile.

- Analysis: Calculate roughness parameters such as Ra (average roughness) and Rz (mean roughness depth).

Coating Thickness Testing:

- Preparation: Ensure the surface is clean and dry.

- Measurement: Select an appropriate coating thickness gauge and place it on the coated surface. The device will measure the thickness based on the chosen method (magnetic induction, eddy current, or ultrasonic).

- Analysis: Record and analyze the coating thickness readings to ensure they meet specifications.

Adhesion Testing:

Preparation: Clean the surface and mark the test area.

- Testing: Use an adhesion tester, such as a pull-off tester or cross-hatch cutter, to apply force to the coating. Measure the force required to detach the coating or assess the pattern of coating removal.

- Analysis: Evaluate the adhesion strength and compare it with required standards.

Surface Contamination Analysis:

- Preparation: Use swabs and solvents to collect samples from the surface.

- Testing: Analyze the samples using appropriate techniques, such as gravimetric analysis or spectrometry, to detect and quantify contaminants.

- Analysis: Compare contamination levels against acceptable thresholds.

Surface and coating quality testing adheres to various international standards to ensure consistency and accuracy. Some key standards include:

- ISO 4287: Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions, and Surface Texture Parameters.

- ASTM B499: Standard Test Method for Measurement of Coating Thicknesses by the Magnetic Method: Nonmagnetic Coatings on Magnetic Basis Metals.

- ASTM D3359: Standard Test Methods for Rating Adhesion by Tape Test.

- ISO 2409: Paints and Varnishes—Cross-Cut Test for Adhesion.

- ISO 14644: Cleanrooms and Associated Controlled Environments—Part 1: Classification of Air Cleanliness by Particle Concentration.

no testing available.