| The Importance of Calibration Traceability

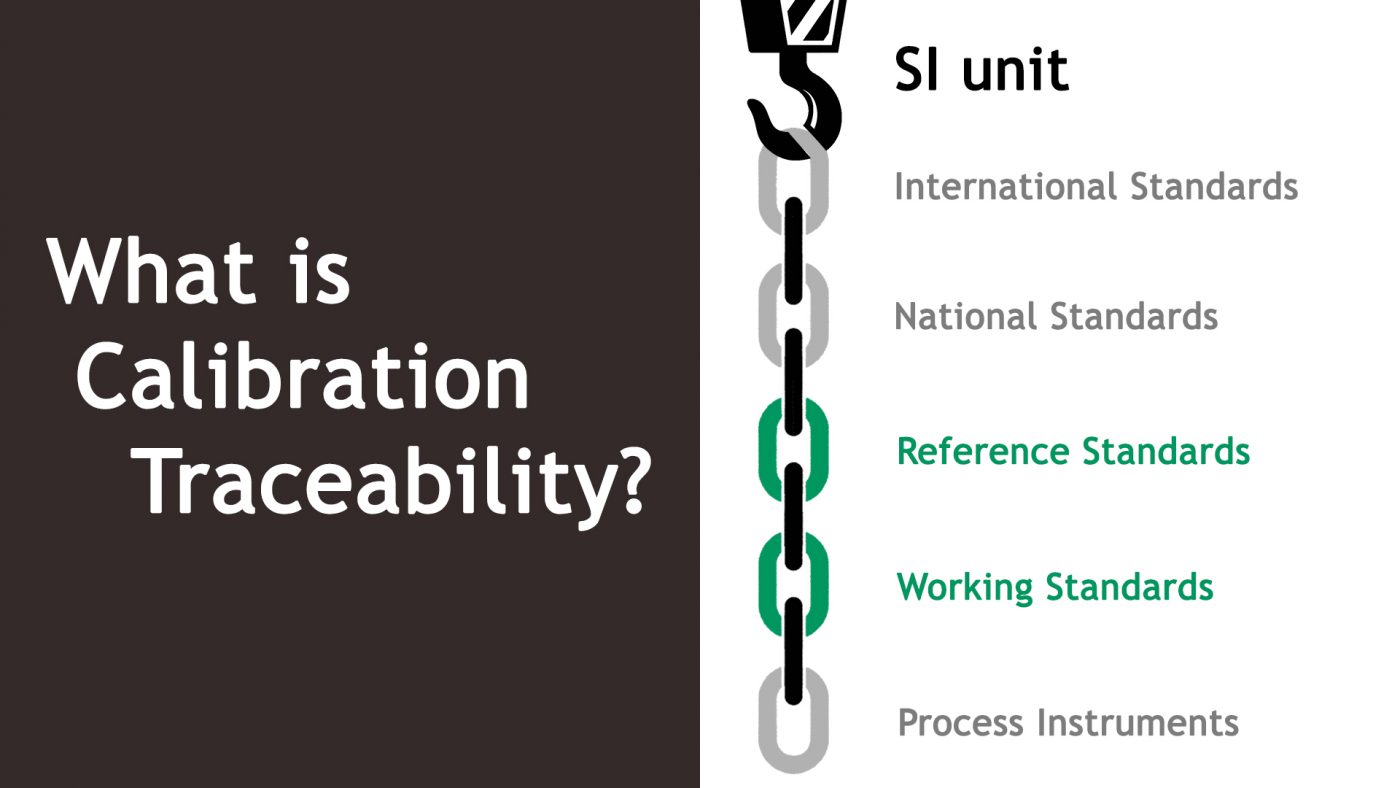

“A calibration performed on an instrument, can become pointless if it cannot be traced to a known reference / standard.” Traceability is defined by the measuring result and whether its value can be compared and related to a working standard or reference. This can be done through a referring to an ‘unbroken chain’ of calibrations that is contributed from each measurement uncertainty. (Refer to the image above) Most importantly, as long as there is a history to trace back to what an item’s value meant, this avoids any risk of confusion during the trace.

Proper calibration ensures that your metrological & material testing equipment are credible and traceable accordingly to its:

How to trace your measurement? Have the following:

NOTE: As long as the measuring result can be traced to a reference of documents with an ‘unbroken’ chain of calibration… This will guarantee competence in both the technical aspects of the measurements and in the quality assurance to ensure that you get a useful and valid “traceable” calibration certificate with a set of results you can rely on. For ISO 17025 Calibration / Consultation : Ms. Sitee Nuraihah Zohari, Calibration Strategist OTHER LINKS: Full List – Scope of Capabilities || ISO / IEC 17025 Certification || ILAC Approval Letter

Brought to you by, Obsnap Calibration Sdn Bhd (1222585-W) which have served over 500+ companies from:

View our full list of clients HERE. |