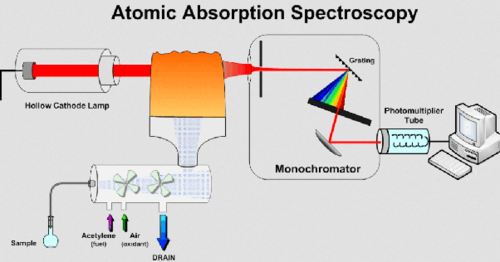

The answer for metals or minerals identification in compounds or trace element analysis (e.g., metals, soil, waste or water drinking, bodily fluids,minerals, all sorts of chemical compounds etc) is Atomic Absorption Spectroscopy (AAS) in the field of Analytical Chemistry. The element analysis can be qualitative (determining what elements are present), and it can be quantitative […]

What if an aerospace O-rings is not properly tested for cycle of extreme cold & Heat (Thermal shock)? In history, That cold rubber became stiff, failing to fully seal the joint and caused the NASA’s space shuttle Challenger tragedy that killed seven astronauts on Jan. 28, 1986 Thermal shock refers to fluctuation in temperature which […]

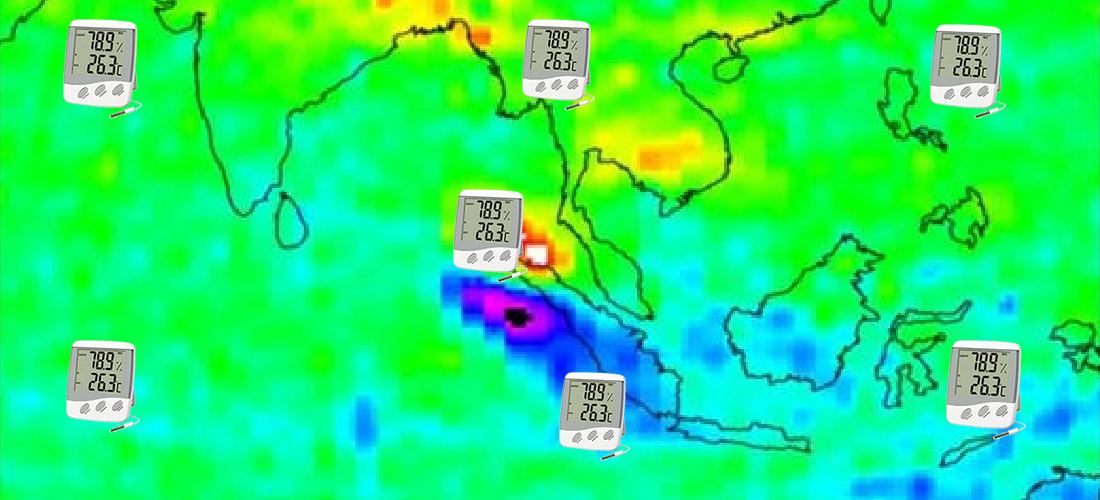

TEMPERATURE CALIBRATION & MAPPING – WAREHOUSE, TRUCK, COLD STORAGE, CLEAN ROOM, ETC.Obsnap Calibration Sdn Bhd provide ISO/IEC 17025 Accredited Calibration. We also provide Temperature & Relative Humidity Mapping for Warehouse, Cold Room and Clean Room. Temperature sensitive materials, foods or pharmaceuticals can degrade at higher temperature therefore it is important to validate laboratory and manufacturing […]

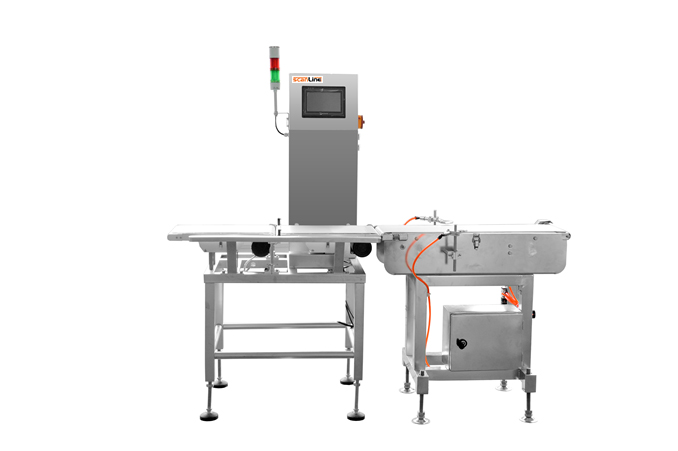

How to ensure product sample weight falls within tolerance all the time and achieve the benefit of savings? One of the vital benchmarks in quality control is measuring the weight of a product. Scanline checkweigher has high-precision weight reading function to check the weight of the product throughout the process with 100% online inspection, in […]

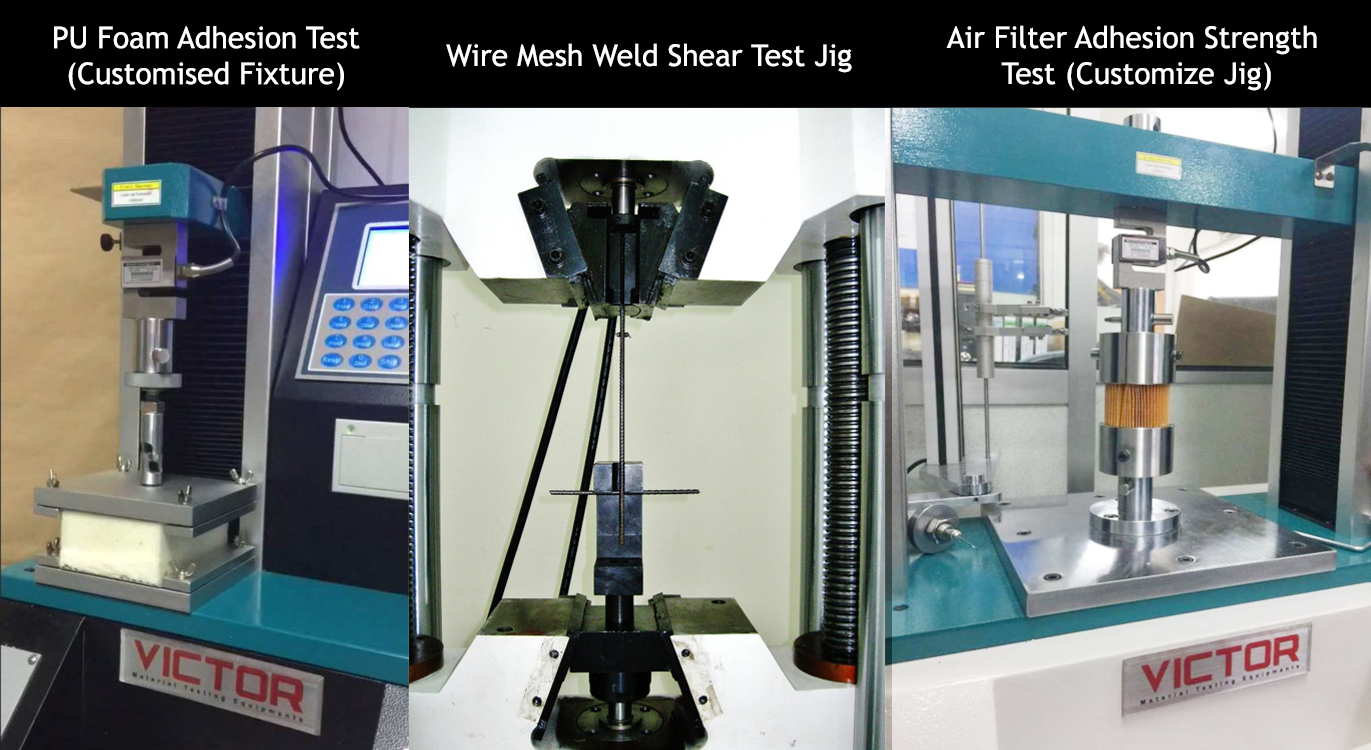

“Tensile testing is a common material testing method to apply tension, load and force onto a sample until it breaks apart.” Tensile testing has been used by quality control departments to assure that their parts & components have product integrity and safety. Various testing methods Destructive testing is used in order to discover a material’s […]

Muffle furnaces are specially designed for heat treatment (with maximum temperature between 1100°C, 1200°C or 1300°C) in a compact and convenient manner. Making it suitable for laboratories, educational institutions, research & development facilities, ceramic studios, industrial laboratories, additive manufacturing and so on. Its heating capability can be supplied by combustion fuel, by electricity (i.e. electric […]

“Quality control for metals & alloys are critical to ensure structure integrity and reliability for the manufacturing use and consumer application…” Benefits of Metallographic Sample Preparation: Analysing the microstructure of the physical structure and components material (with microscopy). Determine if the material has been made/processed correctly Discovering why a material’s quality passed or failed during application & […]

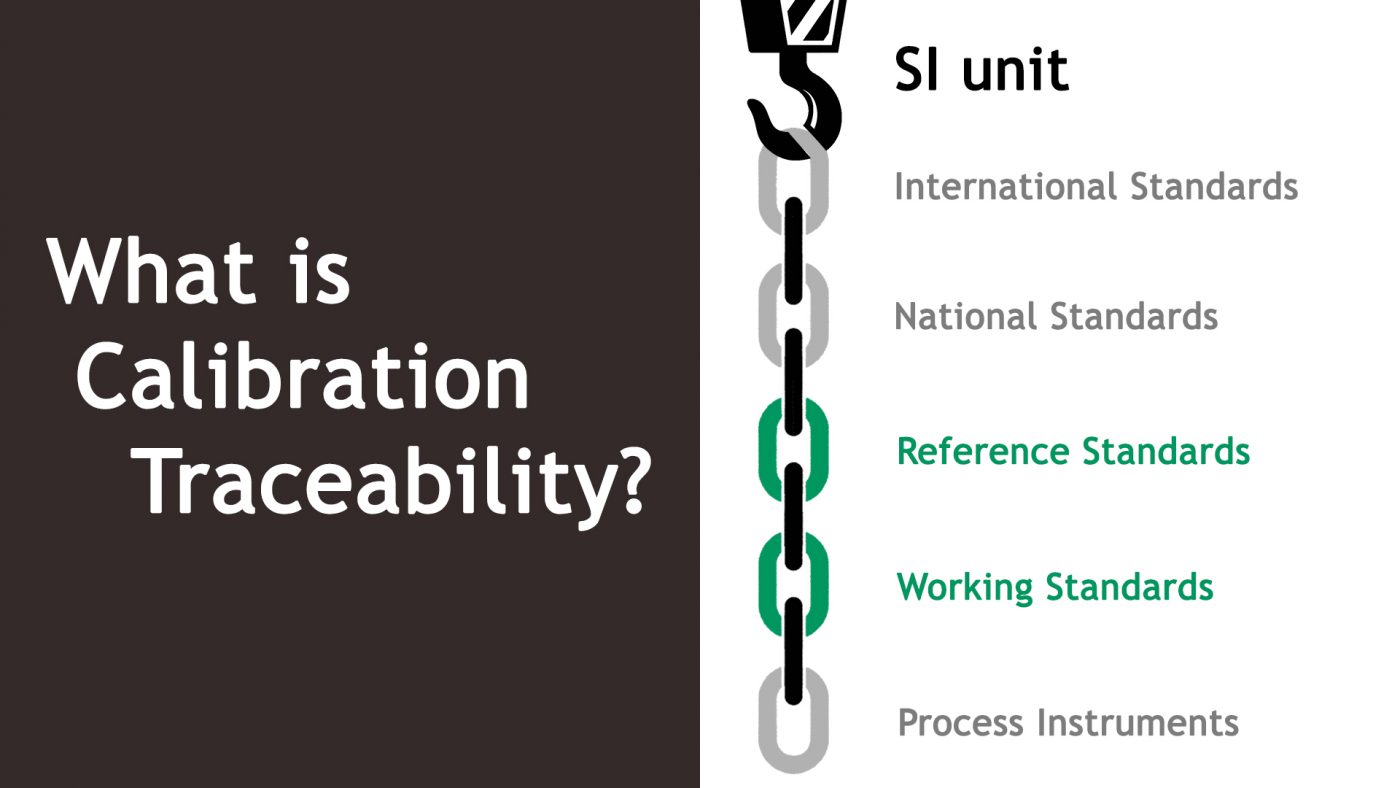

The Importance of Calibration Traceability “A calibration performed on an instrument, can become pointless if it cannot be traced to a known reference / standard.” Traceability is defined by the measuring result and whether its value can be compared and related to a working standard or reference. This can be done through a referring to an […]

“RoHS directive encourages manufacturers to reduce the use of hazardous & toxic materials to ensure user safety and product reliability while preventing future environment pollution.” Benefits of RoHS Directive & Certification Complying with the RoHS directive can encourages manufacturers to: Contribute to a cleaner environment with stricter quality process control, overall reduced number of […]

“Non-destructive measuring instruments like the wall thickness gauge and the ultrasonic thickness gauge, has helped many manufacturers to perform thickness measurement without damaging their products.” Importance of Thickness Measurement Manufacturers can ensure their users’ safety, convenience and product reliability by checking on the thickness of their product. To avoid structure failure & to identify […]