Optimal performance is no coincidence, it’s the result of consistent, professional care.

Our technical team conducts regular inspections, adjustments, and servicing to keep your equipment operating at its best. By identifying and addressing potential issues early, we help you avoid costly breakdowns, improve efficiency, and extend the lifespan of your assets. It’s not just maintenance, it’s a strategic investment in reliability and peace of mind.

Why Preventive Maintenance Matters

In industries where machines drive productivity, prevention is always better than cure. Breakdowns don’t just cause repair bills they disrupt schedules, lower output quality, and create safety risks. Preventive maintenance keeps equipment in peak condition, reducing failures while maximizing return on investment. With Obsnap’s preventive maintenance services, you gain:

Reduced Unexpected Downtime

Routine servicing helps cut unplanned stoppages by an average of 30–40%, keeping production on track.

Optimized Performance

Scheduled calibrations and tune-ups maintain 80–98% of factory-level efficiency.

Extended Equipment Lifespan

Regular care typically adds 2–4 years to machinery life, delaying costly replacements.

Lower Operating Costs

Preventive servicing can reduce emergency repair expenses by up to 25% annually.

Improved Safety & Compliance

Machines are kept within regulatory and safety standards, reducing workplace risks.

Predictable Planning

Pre-scheduled maintenance allows for smoother production scheduling and fewer last-minute disruptions.

Industries We Serve

Preventive maintenance is critical for sectors where uptime, safety, and efficiency are top priorities:

Food & Beverage Processing

Medical & Healthcare

Automotive

Aviation

Oil, Gas & Petrochemical

Manufacturing

Pharmaceuticals & Biotechnology

Logistics & Warehousing

Equipment Types We Handle

Our preventive maintenance expertise covers a wide variety of equipment, including:

Brinell Hardness Testers

Ensuring test accuracy through regular calibration and inspection.

Balancing & Vibration Machines

Checking alignment, lubrication, and sensor health for precise performance.

Hydraulic & Mechanical Test Systems

Monitoring pressure levels, seals, and safety systems to avoid failures.

Electronic Measurement Devices

Calibrating multimeters, oscilloscopes, power supplies, and analyzers.

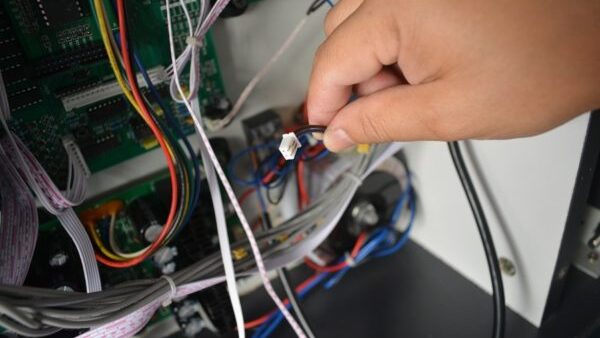

PLC & Automation Systems

Routine inspection of wiring, modules, and software to prevent downtime.

General Industrial Machinery

Preventive cleaning, alignment, lubrication, and parts inspection.

How It Works

Our preventive maintenance follows a structured, proactive workflow:

Review equipment history and operating conditions.

Carry out inspections, lubrication, calibrations, and system checks at planned intervals.

Use tools like vibration analysis, thermal imaging, and load testing to detect hidden issues.

Swap out wear-prone components before they fail.

Verify equipment is performing within optimal parameters.

Provide detailed reports with findings, actions taken, and future maintenance schedules.

Our Repair Services vs Others

| Our Preventative Maintenance | Others |

|---|---|

Scheduled care – regular servicing to prevent breakdowns. | Reactive only – fix machines only after they fail. |

Prolongs machine life – reduces wear and costly downtime. | Frequent failures – higher risk of sudden stoppages. |

Detailed records – maintenance logs and reports for compliance. | No documentation – hard to track service history. |

Why Choose Us

Obsnap Automation is a trusted name in Malaysia for delivering comprehensive preventive maintenance programs. Customers choose us because:

Customized Schedules

Maintenance plans tailored to your exact equipment and usage.

Experienced Engineers

Skilled in both mechanical and electronic system care.

Advanced Diagnostic Tools

Modern testing and calibration equipment used to detect issues early.

Transparent Reporting

Detailed reports outlining work performed and recommendations for future upkeep.

Local, Reliable Support

Quick response across Malaysia with dedicated service teams.

Commitment to Longevity

Focused not just on fixing equipment, but ensuring it serves your business for years to come.

What Our Customers Say

Businesses across different industries rely on Obsnap Automation for their labeling and automation solutions. Here’s how they describe their experience with us:

FAQ

Find answers to the most commonly asked questions about our services, policies, and support. Quick help, all in one place

It depends on the equipment type, workload, and environment. We provide tailored maintenance schedules based on your operation.

Yes. Regular care avoids costly breakdowns, emergency repairs, and premature replacements. It’s a long-term investment.

Absolutely. Our engineers are cross-trained in multiple disciplines to handle diverse equipment needs.

Yes. We often integrate multiple services to ensure your equipment is fully optimized.