Accurate measurements are the foundation of product quality and regulatory compliance.

Our technical team provides meticulous calibration services to ensure every reading, setting, and output meets exact industry standards. Using certified tools and proven processes, we help you minimise errors, reduce waste, and protect your reputation for quality. You can have complete confidence that your equipment will deliver results you can stand behind.

Why Calibration Matters

Even the best machines gradually lose accuracy over time due to wear, environmental changes, or daily operation. When equipment drifts out of calibration, it affects performance, efficiency, and compliance. Regular calibration ensures your machines deliver reliable results, protect your investment, and keep operations running smoothly.

Inaccurate Results

Equipment that is out of calibration can produce faulty readings, inconsistent quality, or defective products. Even minor deviations can cause 5–10% errors in measurement-sensitive applications.

Compliance Issues

Accurate calibration is essential to meet industry standards and regulatory requirements. Without it, audits, safety inspections, or certifications may fail.

Downtime & Waste

Misaligned or uncalibrated machines often trigger unnecessary rework, material loss, or even equipment damage, resulting in costly delays.

Optimized Performance

Regular calibration restores machines to factory-level precision, ensuring they operate at peak efficiency.

Extended Equipment Lifespan

Maintaining proper calibration reduces undue stress on components, extending the service life of critical assets.

Industries We Serve

Our repair services are trusted across a wide range of industries, each with unique equipment and operational demands. We understand the critical role machines play in these sectors and tailor our repair approach to suit each environment:

Aerospace & Automotive

Oil & Gas / Energy

Electronics & Semiconductors

Manufacturing & Heavy Industry

Food & Beverage

Types of Calibration We Provide

At Obsnap Automation, we understand that every industry relies on precise measurements to maintain quality, safety, and compliance. That’s why we provide a wide range of professional calibration services designed to keep your instruments accurate, reliable, and ready for audit requirements.

Dimensional Calibration

Ensures tools such as vernier calipers, micrometers, dial gauges, and height gauges provide exact readings for critical measurements. Dimensional accuracy is essential in industries like manufacturing, machining, automotive, and aerospace, where even the smallest deviation can affect product quality.

Electrical Calibration

Covers instruments like multimeters, oscilloscopes, power analyzers, and signal generators. Electrical calibration ensures consistent and accurate performance, reducing the risk of faulty readings in electronics, telecommunications, R&D labs, and power utilities.

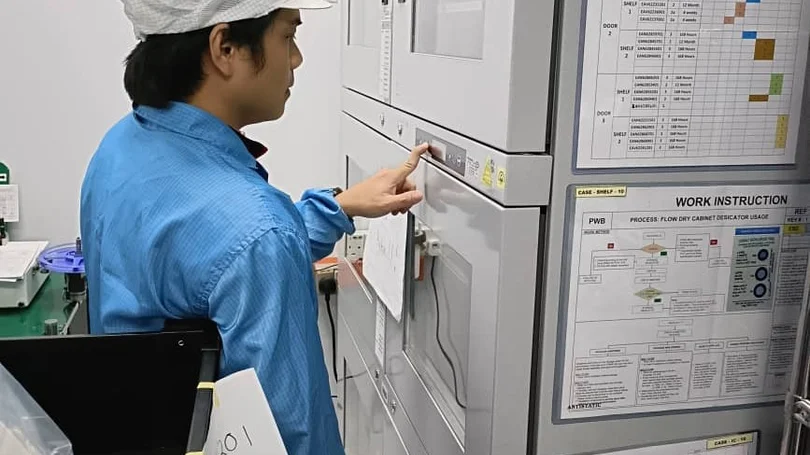

Temperature Calibration

From thermocouples, RTDs, and infrared sensors to ovens, incubators, and climate chambers, temperature calibration ensures accurate monitoring and control. This is especially critical in industries such as food & beverage, pharmaceuticals, HVAC, and cleanroom manufacturing.

Pressure Calibration

For devices like pressure gauges, transmitters, manometers, and regulators, we provide precise calibration to guarantee safe and accurate pressure control. This service supports applications in oil & gas, chemical processing, hydraulics, pneumatics, and medical equipment.

Flow Calibration

Involves flow meters, rotameters, and control devices used in water treatment plants, chemical dosing, fuel management, and HVAC systems. Proper calibration helps improve efficiency, maintain accuracy, and minimize costly errors in fluid handling.

Torque & Force Calibration

Includes instruments like torque wrenches, load cells, dynamometers, and tensile testing machines. This ensures accurate force and torque application, which is vital for automotive assembly, aerospace engineering, construction, and quality testing labs.

How It Works

We follow a systematic, transparent process to ensure every repair is reliable:

We assess your equipment and plan calibration intervals.

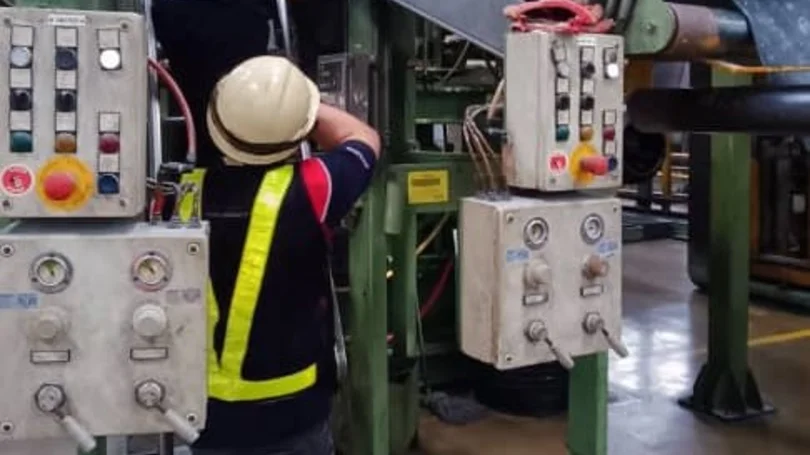

Machines are received in our lab, or our engineers calibrate at your site.

Instruments are measured against traceable reference standards.

Equipment is fine-tuned to restore accuracy.

Detailed calibration reports with measurement data and traceability.

Machines are returned or signed off as ready for production.

Our Repair Services vs Others

| Our Calibration | Others |

|---|---|

Skilled technicians – experienced staff ensure correct setup and testing. | Inexperienced staff – risk of errors during calibration. |

Regular reminders – customers are notified when re-calibration is due. | No follow-up – machines fall out of spec without anyone noticing. |

On-site or in-lab service – flexible options depending on customer needs. | Limited service – only one option, causing delays or inconvenience. |

Why Choose Us

Calibration is not just a service it’s a safeguard for your operations. Clients choose Obsnap Automation because:

Accredited & Traceable

Calibrations are traceable to international standards.

Comprehensive Scope

Covering mechanical, electrical, thermal, and process equipment.

Certified Engineers

Experienced calibration specialists ensure accuracy and reliability.

On-site & In-house Options

Whether at your facility or in our service center, we deliver flexible repair solutions.

Detailed Documentation

Clear reports to support audits and maintain certifications.

Flexible Options

On-site or lab-based calibration for minimal downtime.

What Our Customers Say

Real businesses trust Obsnap Automation for their labelling and automation needs. Here’s what some of them shared:

FAQ

Find answers to the most commonly asked questions about our services, policies, and support. Quick help, all in one place

Typically once a year, but critical machines may need more frequent calibration depending on usage and compliance requirements.

Yes. Every calibration comes with a traceable certificate that meets ISO requirements.

Yes, we offer both on-site calibration and in-house services depending on your needs.

Our team provides adjustment, troubleshooting, or recommendations for repair/replacement.