Hanna Instruments HI510 Universal Process Controller

The HI510 is made to adjust to each user’s particular process control needs. The controller has a sizable backlit dot matrix display for simple viewing and offers a simple configuration interface.

The controller makes use of multi-color LEDs to make it simple to see if the instruments are on hold, in alarm mode, or have their relays activated. The low profile vulcanized rubber keypad or an RS485 connection to a PC running the HI92500 Windows® compatible software are the only two ways to perform programming operations.

- Digital input for pH and ORP probes

- Up to 5 relays for control and cleaning sequence

- Up to 4 analog output for control and monitoring

- The HI510 is a sophisticated universal process controller that may be set up for a wide variety of applications that call for the monitoring and/or control of process parameters. It has a digital probe input that uses sensors to measure a parameter and automatically detects and updates the controller with that information.

- Up to 5 control relays and 4 analog outputs may be installed on this controller. The control relays can be programmed for on/off, proportional, or PID (Proportional Integral Derivative) control types. They can also be used to create cleaning sequences that are triggered by digital inputs or according to a schedule. The remote devices that can utilise the scalable analog outputs include SCADA, PLCs, and chart recorders. Dosing pumps and valves that take a 0/4-20 mA output can be controlled by the analog outputs.

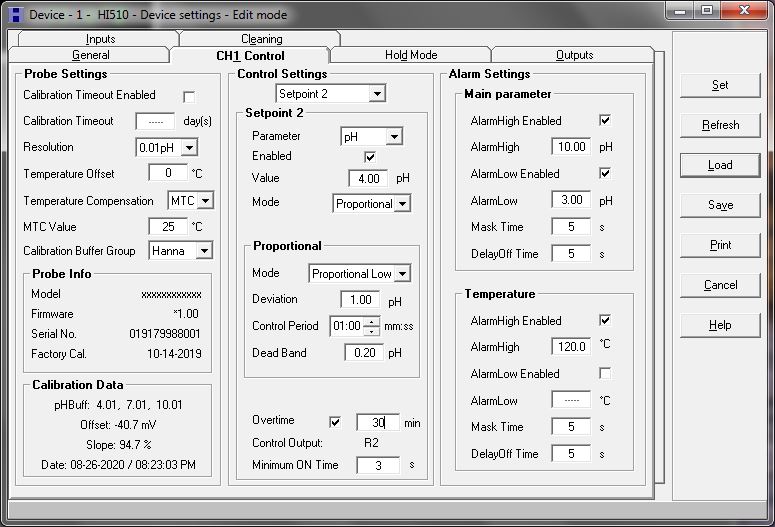

- Utilizing the HI92500 software, the RS485 digital output of the HI510 enables up to 32 devices to be linked to a single line and inspected and programmed remotely. A graphic user interface offered by the HI92500 software enables settings to be modified and stored for transfer to another HI510 controller.

- For watertight integrity, the HI510 NEMA 4X enclosure incorporates sealed cable glands. The HI510 may be mounted to a wall, pipe, and panel thanks to the adaptable mounting kits.

General Design Features

Backlit Dot Matrix LCD with LED indicators

Visual indicators for meter status, alert, and relay activation are available on a large backlit LCD.

NEMA 4X Enclosure

Enclosure with a 1/2 DIN NEMA 4X rating for use in outdoor and industrial settings.

Versatile Mounting Options

Choose from alternatives mounted on the wall, pipes, or panels.

USB-C Connectivity

Flash Drive Compatible

Transferring logged information and events to a flash drive as a.csv file so they may be viewed on Windows, OS X, or Linux-based systems.

Logged Data

Along with relay control settings and calibration data, information is stored at predetermined intervals. Up to 100 lots of data can be kept, each having 8600 records.

Event Management System

Any modifications, alarm, error, and warning activations, as well as calibration data, are all included in logged events.

Low Voltage Connections

Isolated High Voltage Section

The low voltage connecting region is separated from the high voltage area to lessen the risk of shock.

RS485 Digital Connectivity

Up to 32 devices can be connected to an RS485 output for remote programming and monitoring.

Digital Inputs and Analog Outputs

Extractable terminal blocks are used for digital probe inputs, digital trigger inputs, and analog outputs to simplify wiring.

High Voltage Connections

Replaceable Slow Blow Fuses

Replaceable 5A slow blow fuses are used to protect all relays as well as the line power input.

SPDT and SPST Programmable Relays

Programmable relays with a maximum of 5 that can be used for control or washing cycles.

Fail Safe Alarm Technology

Using fail-safe alarm technology, a relay is switched from being ordinarily open to being normally closed in order to power a remote alarm device.

Programming HI510 remotely using HI92500 Software

Relay Control Modes

On/off, proportional, or PID control types can be configured for set points for control activities. With tight control and the flexibility of programming, a set point can be adjusted to perfection while avoiding overshoot and chemical waste.

Configurable Alarm System

Red Alarm LEDs will glow and are clearly visible from a distance. They can be configured for set points and temperature or actuated by aberrant operation. Until the alarm condition is addressed, all relays that are configured for control are deactivated.

Auto-cleaning cycle

The cleaning function enables the programming of one or more wash cycles, and depending on the type of washing necessary to keep probes in good condition for accurate results, relays can be used to activate valves, pumps, or compressed air.

Scalable Analog Outputs

For greater resolution, analog outputs can be adjusted to apply 0 to 20 mA or 4-20 mA to a specified range. When placed in hold position during maintenance, including calibration, analog outputs can be set to send a 22 mA signal.

| SKU | HI510-web |

|---|---|

| Product Name | Universal Process Controller – HI510 |

| Quote Required | Yes |

| Dosing Control | on/off, proportional and PID |

| Dosing Terminals | Up to 5 relays (independently configurable for process variables, Hold & Cleaning functions) Electromechanical relay SPDT and SPST contact outputs 5A – 250 Vac; 5A – 30 Vdc (resistive load) Fuse protected |

| Alarm Relay Set Point | Up to 5 relays (independently configurable for process variables, Hold & Cleaning functions)

Electromechanical relay SPDT and SPST contact outputs |

| Over Dosing Control | yes |

| System Error | yes |

| Analog Ouput Signal | 2 or 4 independent, galvanically isolated outputs 0 – 22 mA configurable as |

| Analog Ouput Accuracy | ±2% full scale |

| Digital Input Signal | independent, galvanically isolated inputs (configurable for Hold & Cleaning functions) On state |

| Digital Output Signal | RS485 |

| Backlight | yes |

| Power Consumption | 15VA |

| Enclosure | *Single case ½ DIN, type NEMA4X, IP65 ingress protection |

| Installation Category | II |

| Panel Cutout | 1/2 DIN (brackets ordered seperately) |

| Input Channels | one digital input with RS485 interface |

| pH Electrode | HI10X6 series – pH and Temperature (ordered seperately) |

| ORP Electrode | HI20X4 series – ORP and Temperature (ordered seperately) |

| Logging Type | Interval log, up to 100 files, maximum 8600 records on each stored file. When the maximum limit of 100 stored files is reached, the most recent file will automatically erase the oldest one. Event log, maximum 100 records. When the maximum limit i |

| Connectivity | RS485 serial port – Remote monitoring and control USB-C port – Retrieve log files and firmware upgrading |

| GLP | yes |

| Calibration Timeout Reminder | yes |

| Analog Output | up to 4 based on configuration ordered |

| Display | Graphic LCD, 128 x 64 pixel B/W with backlight |

| Power Supply | 100 – 240 Vac ±10%; 50/60 Hz; 15VA; fuse protected (2A, 250V slow blow fuse) |

| Environment | -20 to 50 ºC (-4 to 122 ºF); maximum 100% RH non-condensing |

| IP Rating | IP65 |

| Dimensions | Width 144.0 mm (5.7”) x Height 144.0 mm (5.7”) x Depth 151.3 mm (6.0”) |

| Weight | Approximately 1.6 kg (3.5 lb.) |

| Ordering Information | HI510-0540 universal process controller with 5 relays and 4 analog outputs is supplied with 3m power cable, cable gland set, instrument certificate, and instruction manual. |

| Notes | *For a water tight seal, tighten the front four screws on the front casing to 13.3 lbf·in (1.5 N·m, maximum 2.0 N·m), of torque. |