Hanna Instruments HI981413 Groline Nutrient Dosing System

The reservoir tank’s appropriate nutrient solution concentration level was engineered to be maintained at a low cost for hydroponic or greenhouse growers.

The HI981413 GroLine Nutrient Dosing System is a total system with an integrated chemical dosing pump and smart process controller. To dose the stock fertilizer, simply provide it in line with the recirculation pump while inserting the probe and injection valve.

- All in one solution for maintaining the proper nutrient levels

- Industrial process probe with 1/2″ NPT threads for insertion into a re-circulation line

- Available in three configurations including complete kit with panel mounted flow cell

The HI981413 Nutrient Dosing System is intended to keep irrigation water and hydroponics fertilizer nutrient solutions at a constant concentration. The HI981413 measures the concentration of fertilizer in the solution using an amperometric conductivity sensor. The meter can be set up to show data as either TDS or EC (electrical conductivity) (total dissolved solids).

The TDS findings are shown as ppm with a selectable conversion factor ranging from 0.45 to 0.99, while the EC results are shown as mS/cm. By positioning the probe and injection valve in-line with the re-circulation pump to supply the chemical to be dosed, the HI981413 was created as a practical way for horticulturists to maintain the optimal fertilizer concentrations.

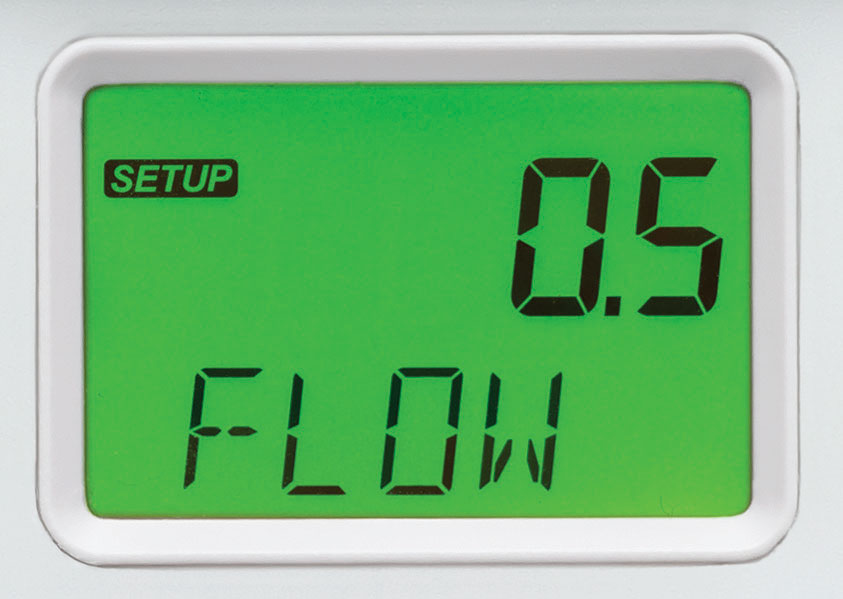

Multi-color LCD

The multi-colored LCD on the HI981413 displays the status of the pool controller. When the control is not enabled, the display is yellow, whereas it is green during normal operation, and it flashes red when an alarm is activated.

Intuitive LCD

With status icons that indicate whether the pump is dosing and the status of the control mode, conductivity or TDS and temperature are both displayed.

Programmable Alarm System

The low and high level alarms for EC/TDS can be enabled or disabled by users using Hanna controllers. All dosage will cease when an alarm goes off. The alarm system also provides overdose protection, in that the meter will enter alarm state if the set point value is not rectified within a predetermined time period.

On-Screen Features

The dosing pumps’ flow rate can be changed from 0.5 to 3.5L/h. Greater chemical doses per unit of time are needed for larger bodies of water than for smaller ones. Similar to the proportional band, the adjustable flow rate enables better control in maintaining a particular set point.

Automatic Proportional Pump Control

Simple on/off control or more complex proportional control, which helps minimize overshooting of the set point, can be used to operate the peristaltic dosing pump. The proportional band employed when applying proportional control will have an effect on the programmed flow rate. The peristaltic pump takes longer to complete one revolution the closer the reading is to the set point. The flow rate preset determines how long it takes to complete one revolution if the reading is outside the proportional band.

Acid Tank Level/Flow Switch Input

Acid Tank Level/Flow Switch InputThe BL100 allows for a connection to an optional level controller or flow switch. This input can be used to disable the dosing pump when there is no chemical left in the reservoir tank or there is no flow due to the pump being turned off.

Built-in Dosing Pump

Peristaltic Dosing Pump

The HI981413 features a peristaltic dosing pump that is superior to diaphragm versions due to the ability to self-prime when there is no liquid in the uptake line.

Brushless Motor

The brushless motor does not have nay gears or brushes that can wear out. A brushless design provides for a long life and little maintenance. The compact stepper motor allows for very precision control over the dosing of the chemical.

Long-life Peristaltic Tubing

The industrial grade peristaltic tubing is chemical resistant and provides for a relatively long-life. As tubing stretches over time it can be easily replaced. No special tools required.

Conductivity electrode with flow cell

Three Configuration Options

The HI981413 is available in multiple configurations including a meter only, meter and probe, and a complete package that includes bypass loop and panel mounted flow through cell. All models include aspiration tubing with filter and dispensing tubing with injection valve.

HI30003 Amperometric Conductivity/Temperature Probe

The HI981413 uses the HI30003 probe that incorporates both conductivity and temperature sensors and connects to the controller with a single waterproof Quick Connect DIN connector.

NPT Threads for In-line and Tank Mounting

The ABS body of the probe has a 1/2” threaded fitting for insertion to an in-line “T” fitting or the flow cell. The back end part of the probe has 3/4” NPT threads for submersion/ tank mounting. The probe body has a hex fitting for tightening snuggly with a wrench.

| SKU | HI981413-web |

|---|---|

| Product Name | Groline Nutrient Dosing System-HI981413 |

| Quote Required | Yes |

| EC Range | 0.00 to 10.00 mS/cm |

| EC Resolution | 0.01 mS/cm |

| EC Accuracy | 2% F.S. |

| EC Calibration | User calibration |

| TDS Range | 0 to 9900 ppm, depends on TDS factor i.e. with TDS factor 0.5, range 50 to 5000 ppm with TDS factor 0.7, range 70 to 7000 ppm |

| TDS Resolution | 1 ppm |

| TDS Accuracy | 2% F.S. |

| EC/TDS Temperature Compensation | automatic |

| Temperature Correction Coefficient | β can be set from 0%/°C to 2.4%/°C; default is 1.9%/°C |

| EC to TDS Conversion Factor | TDS factor selectable from 0.45 to 0.99 |

| EC/TDS Dosing Set Point | on/off control using adjustable set point (0.10 to 10.00 mS/cm; 45 to 9900 ppm, depends on TDS factor) proportional control 0.10 to 10.00 mS/cm; 45 to 9900 ppm, depends on TDS factor |

| EC/TDS Proportional Band | 0.05 to 1.00 mS/cm; 23 to 990 ppm, depends on TDS factor |

| EC/TDS Hysteresis Band | 0.05 to 0.50 mS/cm; 23 to 495 ppm, depends on TDS factor |

| Temperature Range | -5.0 to 105.0°C; 23.0 to 221.0°F* |

| Temperature Resolution | 0.1°C; 0.1°F |

| Temperature Accuracy | ±0.5°C; 1°F |

| Dosing Control | startup delay timer at power-on (0 to 600 sec.) Pump flow control 0.5 to 3.5 Liter/hour (0.13 to 0.92 Gallon/hour) and maximum output pressure 1 atm (14 psi) manual control for pump priming (defined in setup) |

| Alarm Relay Set Point | triggered after 5 sec. if the controller records consecutive readings over or under threshold values |

| Over Dosing Control | overtime protection (1 to 180 min. or Off) |

| Digital Input Signal | galvanically isolated external switches can be attached to stop the pump and activate the alarm (low reagent level) when the switch is open and level alarm is configured in Setup |

| Backlight | intuitive alarm system, using red, yellow and green color coded backlight |

| Power Consumption | 15 VA |

| Enclosure | wall mounted, built-in pump |

| Power Supply | 100 – 240 Vac, 50/60 Hz |

| Environment | 0 to 50°C (32 to 122°F); RH max. 95% non-condensing |

| IP Rating | IP65 |

| Dimensions | 90 x 142 x 80 mm (3.5 x 5.6 x 1.8”) |

| Weight | 908 g (36 oz.) |

| Ordering Information | HI981413-00 is supplied with HI981413 controller, HI30033 EC/TDS/temperature probe, HI7031-012 conductivity calibration solution (1413 μS/cm – 120 ml), plastic beaker, power connection cable, instruction manual and quality certificates for instrument and probe. |

| Notes | *The temperature range may be limited by the probe’s limits. |