Choose the Right Heat Treatment Furnace “Picking the most suitable furnace for an industrial application requires knowledge of the factors & processes needed for the manufacturing & production lines.“ An industrial furnace goes up to 1000°C – 1200°C or higher. Allowing manufacturers to use for its heating & cooling capability on various materials (e.g. metals) […]

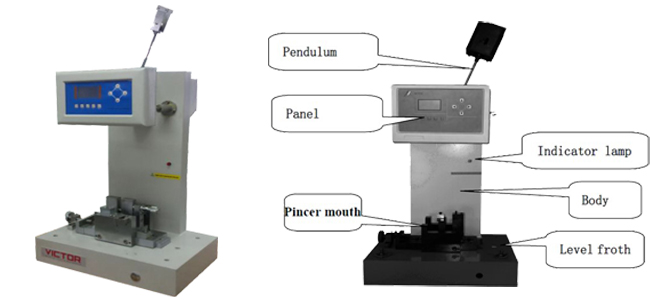

“A material’s toughness determines if it is suitable to be reused for production or to improve its manufacturing quality for their end-product.” Pendulum Impact testing is a type of mechanical testing used to study the toughness of a material to check the product’s ability to absorb impact and to analyse the deformation process before fracturing (by using a falling pendulum weight […]

Having trouble with visual colour checking? Need accurate colour reading? Before colour is painted, printed and produced, manufacturers have to ensure that colour is monitored and accessed during the design stage, the formulation & production process and finally during the quality control process. Which determines the overall outlook on the products while attracting customers… After […]

“Have a Wonderful Festive Break!” From, Obsnap Group of Companies NOTICE: We are closed on 20th & 22nd May 2019 (Monday & Tuesday) We’ll be back on 21st & 23rd May 2019 (Tuesday & Thursday onwards)

Event Name: Metaltech 2019

Date: 15-18 MAY 2019

Venue: MITEC Kuala Lumpur, Malaysia

Booth No: 2006 & 2007, Hall 2

View Original Post, HERE. Melt Flow Testing – An Introduction Melt flow testing measures the ease of flow on the melted thermoplastic* to predict how their resins/pellets will behave in their intended applications. This allows product designers, researchers, manufacturers, and even quality control managers to discover the overall quality and production rate capability of that polymer. *A type of polymer that […]